The nano mask template inherits the advantages of high precision and short processing cycle of laser templates. Through nanotechnology, some nano rare metals are added to the surface, and the metal structure is changed to achieve good bonding, greatly improving the hardness of the steel mesh. The rare metals have a repulsive effect on the flux in the solder paste, thereby greatly reducing the number of screen washes, improving production efficiency and printing quality.

Advantages of Nano stencil:

1) Nanotechnology treatment on the surface of the laser mask inherits the advantages of high precision in opening size and position of the laser mask;

2) Through nanotechnology processing, the physical crystal structure of the material undergoes a transformation, resulting in a significant increase in strength, hardness, and toughness, and a greatly extended service life;

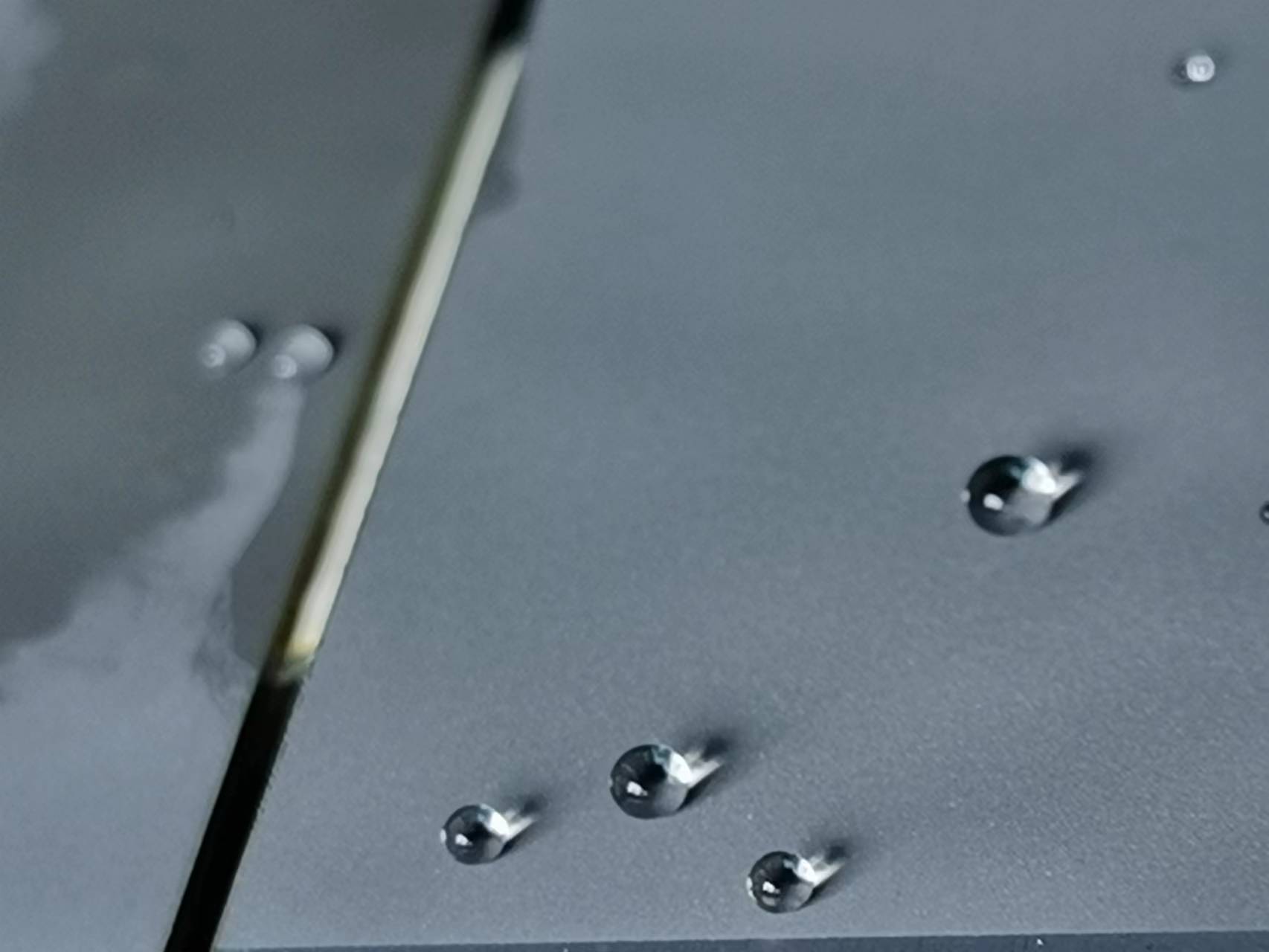

3) The back surface treated with nanotechnology forms a "superhydrophobic surface", which enables the back of the mask to have self-cleaning function, greatly reducing the wiping frequency of the mask and improving production capacity;

4) Reduce the defect rate (greatly reduce low tin, tin balls, bridge connections, etc.)

5) Improve the pass rate once

6) Reduce costs

The nano technology micro ion high-precision mask template truly conforms to the national industrial policy of low energy consumption, high efficiency, and green environmental protection, meeting the industry's high, precision, and fine development direction.